Water is a vital resource, and its responsible management is crucial for all partners in the water industry. Accurately measuring water flow through their systems is key, both for conserving water effectively and ensuring consumers only pay for the water they use. For that reason, the American WaterWorks Association (AWWA) maintains accuracy standards to which meter manufacturers must meet or exceed.

Determining Accuracy Standards

In North America, the AWWA is the governing body for the water industry and is the organization that sets those standards and recommendations for all types of water meters. The AWWA’s accuracy standards reference two types of flow rates to define accuracy, “Normal Flow” and “Minimum Low Flow”, which vary depending on the size and type of the meter. For example, the minimum low flow standard for a positive displacement and ultrasonic meter varies due to the nature of their respective designs.

The AWWA's allowable accuracy for most revenue-generating meters is as follows:

- Normal Flow: 98.5% - 101.5% (or 100% @ +/- 1.5%)

- Minimum Low Flow:

- Positive Displacement Meters: 95% - 101%

- Ultrasonic Meters = 95% - 105% (or 100% @ +/-5%)

According to the AWWA standard, if a perfect meter is one that achieves 100 percent accuracy, then an acceptable meter can register between 98.5 to 101.5 percent. The minimum flow, or the extended low flow as it is often called, allows for less accuracy due to the more challenging task of measuring lower flow rates.

Reading and Interpreting Accuracy Curves

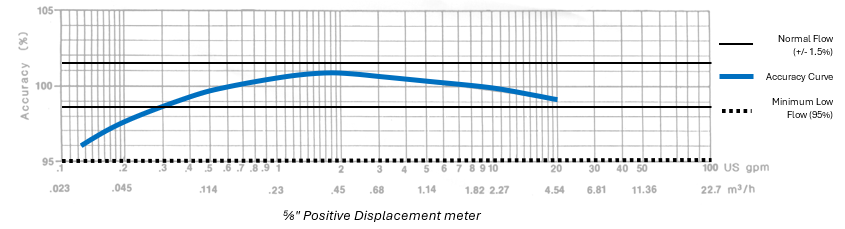

All meter types have an accuracy curve that visually charts a meter’s expected performance across a flow range. The expected accuracy is measured along the “y-axis” and the flow rate from low flow to high flow is measured along the “x-axis”.

Mechanical Meter Curves

Throughout the history of the AWWA, mechanical water meters have been the primary type of water meter. Mechanical meters’ moving parts lead to varying degrees of accuracy at different flow rates, as displayed in the chart below.

Looking at the chart, the curved line is indicative of a 5/8” Positive Displacement meter’s expected accuracy across the stated flow range. An accuracy curve like this is within the accuracy limits stipulated by the AWWA for both normal and minimum flow ranges.

Ultrasonic Meter Curves

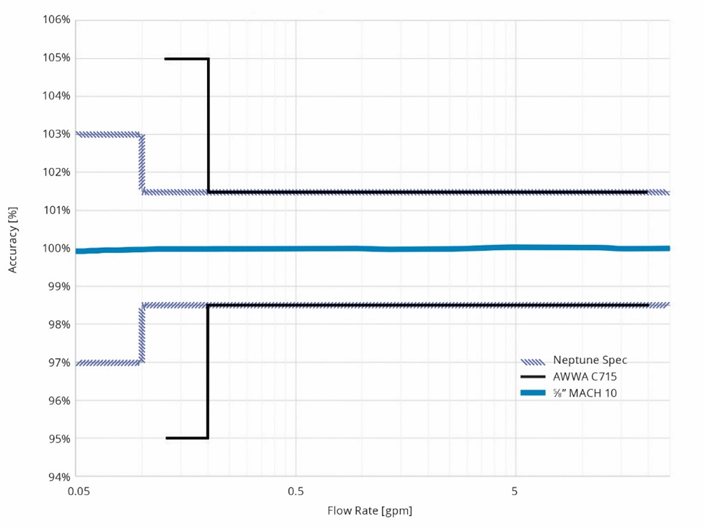

An ultrasonic meter’s curve is more of a straight line due to the lack of moving parts which cause variability at different flow rates. Take this accuracy curve for a Neptune 5/8” MACH 10 for example:

The meter’s accuracy curve is less than +/- 1% in deviation across the meter’s flow range. The chart also illustrates how Neptune’s ultrasonic low flow accuracy standard is more stringent (+/- 3%) than the AWWA’s low flow accuracy standard (+/-5%).

In addition to having very little variability, an ultrasonic meter’s curve is sustainable due to the absence of moving parts that wear down over time. An ultrasonic meter, like Neptune’s MACH 10, will maintain its accuracy over the life of the meter.

Accuracy Curves Build Confidence

A water meter measures the amount of water flowing through it and serves as a "cash register" that sits between a city's water utility and their customers (or citizens). Water meters also provide a means of monitoring usage by municipalities to manage supply and demand. For governments, the data provided by water meters helps with conservation efforts related to this precious natural resource. As such, it is imperative for water meters to remain accurate through their lifespan to ensure fair billing practices, customer confidence, proper infrastructure planning, and conservation efforts.

For more information about Neptune’s ultrasonic metering options visit neptunetg.com/mach10.

Don’t Want to Miss a Post?

Subscribe here to be notified when new information is published.